CABSYS Rail NG

The future of the elevated cable duct system

The new generation CABSYS Rail NG – available in two sizes like its predecessor – is a self-supporting, elevated cable duct system made of GRP with a system length of 6 metres. The system is specially designed to run signal, communication and power cables along railway lines and provides optimum protection for the sensitive infrastructure.

Only one narrow path is needed to install the GRP cable ducts. The GRP cable ducts are easy to transport and install – a great advantage, especially in difficult terrain. The new cable duct cover in particular makes installation easier with just a "click", which makes screwing on of the cover with at least six screws, as was previously the case, unnecessary. This saves you valuable time.

The cable duct system is designed for a cable load of 45 kg/m (CABSYS Rail NG size 1) or 90 kg/m (CABSYS Rail NG size 2). CABSYS Rail NG is not suitable for use in tunnels.

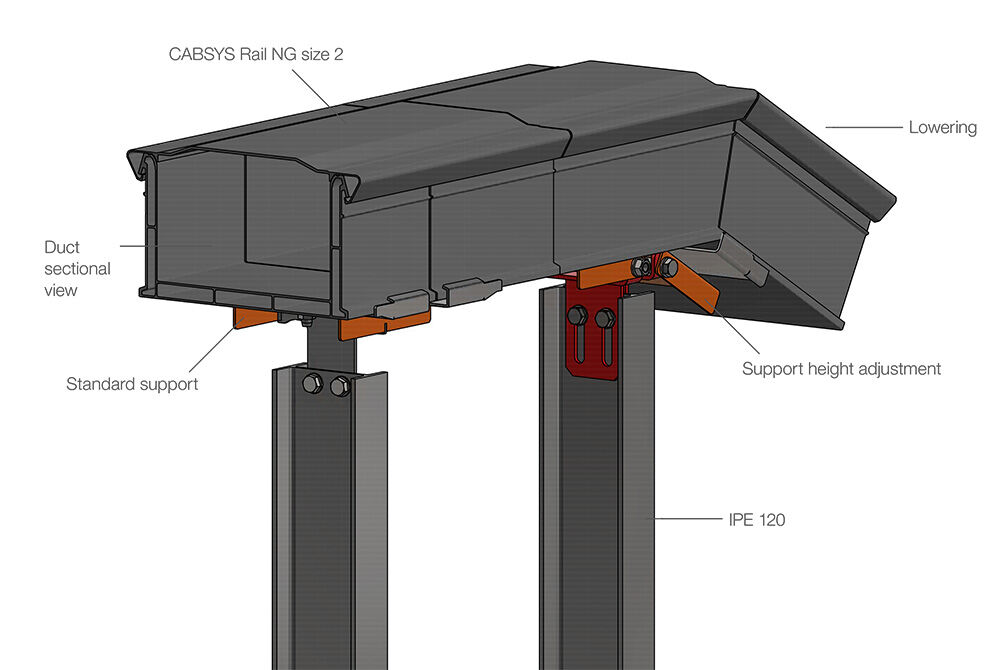

System structure

The new generation (NG) of our CABSYS Rail cable duct system is double-walled, making it even more stable and resistant. The system is very easy to install thanks to the few components: Only four screws are needed to complete the installation of a support on the IPE 120 steel supports. The lid can be easily "clicked on" without tools.

Technical information

System length

6 m self-supporting, elevated cable duct system. The maximum permissible stand distance is 6 m.

Area of application

The system is suitable for signal, communication and power cables along railway lines. It is particularly suitable for elevation in difficult terrain and requires only a narrow path. The path must be outside the safety area according to EBO.

The system is NOT suitable for use in tunnels.

Cross sections

| Clear width | Clear height | Usable cross-section | |

|---|---|---|---|

| CABSYS Rail NG size 1 | 100 mm | 150 mm | 15,000 mm² |

| CABSYS Rail NG size 2 | 250 mm | 150 mm | 37,500 mm² |

Cable load

The CABSYS Rail NG cable duct system is designed for a cable load of 45 kg/m (size 1) or 90 kg/m (size 2).

Cable duct and cover

Glass-fibre reinforced plastic in accordance with EN 13706/E23, halogen-free, non-woven in the top cover layer for weather resistance. Even in low temperatures, the cable duct system does not become brittle. Fire protection to fire class K1 in accordance with DIN 53438 part 2. In the event of a ground fire in accordance with the standard, temperatures < 70 °C are maintained inside the duct thanks to the double-walled design.

Earthing

The system is designed so that no protective earthing measures are required in accordance with DB AG Guidelines 997.0204 and 997.0242.

Electrical properties

Breakdown voltage for duct and cover in accordance with DIN VDE 303 Part 21 and Part 30 > 30 kV.

Mechanical loads

Here is a small excerpt of the mechanical loads which the system is designed for.

- Man load vertical in field centre 0.75 kN

- Snow load on the ground 2.4 kN/m²

- Horizontal snow load due to snow gliding, snow crawling and snow clearance is also taken into account. Of course, horizontal wind loads and loads caused by suction/pressure from train traffic are also taken into account. The system is designed to be torsion-resistant.

Materials

Screws and attachments

All attachments and screws made of galvanised steel. Special parts made of A2 stainless steel in exceptional cases.

Stands

Steel support and frame, hot-dip galvanised in accordance with EN 1461-TZNO. The front edges of the supports are cold-dip galvanised with zinc dust paint. The supports are made of material S235JRG2.

Special features of the route

We have developed special components for all the special features that occur in the course of the path.

Downloads

CABSYS Rail NG

Size 1 and 2

All components for the new CABSYS Rail NG system can be found in our online product catalogue.